Cooling tower packing is a vital component in the structure of cooling towers, which plays a central role in the removal of heat caused by industrial processes or air conditioning systems. Cooling towers are widely used in various industries to remove excess heat produced. The packing of the cooling tower is an integral part of this system, which greatly helps to improve the cooling process in the cooling tower by increasing the contact surface of hot liquid and air.

The main function of a cooling tower is to transfer heat from a process fluid (such as hot water or steam) to air. In this heat exchange, the cooling tower packing acts as a medium through which the hot water flows and facilitates the transfer of heat to the air. Packing creates a large surface and thus increases the effective contact between the weather and the air passing through the tower and improves the performance of the cooling tower.

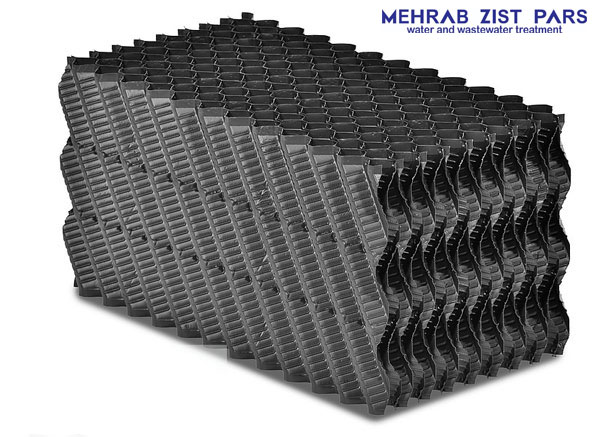

Cooling tower packings are usually made of durable and chemical-resistant materials such as PVC (polyvinyl chloride) or other plastics. A packing design consists of a series of closely spaced sheets or structures that create a labyrinthine path for flowing water. This complex configuration allows for optimal exposure of water to air and maximizes the heat transfer process.

One of the key advantages of using cooling tower packings is their ability to significantly increase the available surface area for heat exchange in a compressed space. As the warm water flows through the fill, it spreads throughout the complex network of channels, creating a thin layer that is exposed to the air. This thin layer allows efficient evaporation and heat transfer. In addition to improving heat transfer, the packing of cooling towers plays an essential role in reducing the escape of water droplets from the cooling tower. The packing design helps minimize water loss from the cooling tower, ensuring that water is effectively retained within the tower while maximizing cooling tower efficiency.

The efficiency of a cooling tower largely depends on the quality and design of the packing. Properly designed and maintained packings contribute to the overall effectiveness of the cooling tower in terms of heat dissipation and water retention. Regular cleaning and maintenance is necessary to prevent deposits or flaking of the packings in order for them to be effective.

Application of cooling tower packing

Cooling tower packings are used in various industries. In general, in any industry where heat removal is necessary in part of its process and a cooling tower is used, packing also plays a vital role. In the following, we mention some of the most important applications of cooling tower packing.

power plants

In power plants, in a part of the steam cycle process inside the condenser, it turns into a liquid by hitting the pipes containing cooling water and enters the production cycle again. The temperature of the water inside the condenser tubes increases by receiving heat from the steam, that’s why they use the cooling tower to reduce the temperature of the condenser water. Different types of cooling tower packings are used in power plant cooling towers.

Manufacturing industries

Cooling tower packing is used in chemical processing industries to cool various chemical reactions and processes that produce heat.

In addition, industries such as steel production use cooling tower packing to cool water used in various stages of production, including cooling hot metal surfaces and equipment.

Air conditioning systems

In air conditioning systems that use water condensers, a cooling tower is used to reduce the temperature of the water leaving the condenser. Cooling tower packings are a vital and integral part of the cooling tower of air conditioning systems.

Refinery industries

Cooling tower packing is used in oil refineries to cool the water used in refining processes and helps to manage the temperature in different refining units.

Plastic and rubber manufacturing industries

Packed cooling towers are used to cool the water used in the injection molding process in the plastics industry.

Food and beverage industries

Cooling tower packing is used to control the temperature during the fermentation and distillation processes in the production of beverages.

Large central servers

In large data centers, cooling tower packing is sometimes used to dissipate heat generated by servers and electronic equipment.

Pharmaceutical industry

Cooling towers along with packing are used in drug production to control the temperature in different stages of production.

Textile factories

During dyeing processes, cooling tower packing helps to cool the water used in the dyeing process in textile factories.

Petrochemical industries

In petrochemical industries, cooling tower packing is used to cool water used in various processes, including heat exchangers.

The main function of cooling tower packing in these applications is to maximize the contact surface between water and air. This increases efficient heat transfer by evaporating a thin layer of water passing through the cooling tower packing ducts. As a result, the heat is dissipated to the atmosphere and the cooled water can be recirculated for reuse in industrial processes. Proper selection and maintenance of cooling tower packing is necessary to ensure optimal performance and energy efficiency in these diverse applications.

Application of cooling tower packing

The choice of cooling tower packing is an important decision that can significantly affect the efficiency and performance of a cooling tower. In the following, we mention the important points that should be considered in choosing the packing of the cooling tower.

Heat transfer efficiency

The main task of cooling tower packing is to increase heat transfer. To ensure optimal heat exchange between water and air, consider the design and packing efficiency of the cooling tower.

surface area

Packing should provide a large surface area to maximize contact between water and air. This is perhaps the main task of packing that will increase the efficiency of the cooling tower.

Material selection

Choose materials that are durable, corrosion resistant and suitable for the specific conditions of the cooling tower environment. Common materials include PVC (polyvinyl chloride) and other plastics.

Packing type

There are different types of cooling tower packing such as film pack or splash packing. Choose the right packing depending on the type of application and your needs.

Water quality

The quality of water used in the cooling tower can affect the performance and lifespan of the packing. Make sure the packaging you choose is compatible with the quality of the available water.

Maintenance requirements

The ease of maintenance and cleaning of the selected packing is another thing that you should pay attention to while choosing the packing of the cooling tower.

Resistance to sedimentation

Choose packaging that is resistant to scaling and fouling, as these issues can reduce heat transfer efficiency and increase the need for maintenance.

Environmental considerations

Consider the environmental impact of the chosen packaging material. Environmentally friendly options may be more compatible with secondary goals of the organization such as sustainable production.

Price and long term value

While initial prices are important, consider the long-term quality of cooling tower packing. Investing in quality packing that requires less replacement can be cost-effective in the long run.

Reputation and credibility of the manufacturer

Choose cooling tower packing from reputable manufacturers with a history of producing reliable and high-performance products. In this way, you can use after-sales services with ease.

Compliance with regulations

Ensure that the packaging chosen complies with industry and environmental regulations. This is important for both operational and regulatory compliance.

Compatibility with tower design

Be sure to consider the design and configuration of the cooling tower. The packing must be compatible with the tower structure and air flow patterns in order to perform optimally.

By carefully considering these points, one can make informed decisions when choosing cooling tower packing and ultimately contribute to the efficiency, reliability and longevity of the cooling tower system.

The necessity of using packing in the cooling tower

As mentioned earlier, the use of packing in cooling towers has an important effect on their efficiency and performance. Cooling towers The optimal use of packing in these towers is necessary to improve the heat exchange process between water and air, and various factors emphasize its importance.

The main function of cooling towers is to transfer heat from the process fluid (such as hot water or steam) to the surrounding air. The presence of packing in the structure of the tower helps to provide a surface for better contact between water and air, this work increases the efficiency of the cooling tower. By creating a thin layer of water on the surface, packing helps to increase the evaporation of water and thus reduce its temperature.

Another necessity of using packing in the cooling tower is that it prevents water droplets from escaping from the tower and thus reduces water loss.

In general, the use of packing in cooling towers is very important to improve heat exchange, protect water resources and increase energy efficiency. These measures not only contribute to sustainable water management, but are also in harmony with the principles of environmental protection.

Different types of cooling tower packing have been designed and manufactured in order to increase the contact surface of fluid with air. In the following, we introduce the most common types of cooling tower packing.

Splash packing

Splash packing usually consists of a series of bars or grids placed at the top of the cooling tower. These bars or grids break the water flow into droplets as they fall. The droplets created by the fluid increase the contact surface with the air and improve the temperature exchange between the fluid and the cooling tower. This design is particularly effective in cross-flow cooling towers.

Splash packing is commonly used in cooling towers where water flows vertically and air moves horizontally, such as cross-flow configurations.

Film packing

Film packing is made of closely spaced vertical plates or surfaces through which water flows. The surfaces are designed in such a way that they form a thin layer of water.

The thin layer maximizes the surface area for air and water interaction and optimizes the cooling process. Film packing is suitable for both counter-flow and cross-flow cooling towers. Due to its compatibility, film packing is widely used in various cooling tower configurations and provides good thermal performance.

Structured packing

This type of packing has structural and corrugated sheets that significantly increase the available surface for heat exchange. The structured design improves heat transfer efficiency and minimizes air resistance, helping to improve cooling performance. Structured packing is suitable for counterflow cooling towers, especially in applications where high efficiency is critical.

Splash film packaging

By combining the features of each splash packing and film packing, splash film packing is made. The splash film packing helps to spray and spray the fluid and also causes the formation of a thin film of the fluid. In this way, with the help of both mechanisms, it increases the level of heat exchange and, as a result, improves the performance of the cooling tower.

Network packing:

Grid packing consists of bars or parallel grids constructed to promote uniform water distribution. The arrangement of the bars facilitates water flow and maximizes air contact, resulting in improved heat exchange efficiency. Grid packing is commonly used in counter-flow cooling towers and causes uniform distribution of water throughout the packing.

Vertical flow packing

Vertical flow packing has vertical plates or surfaces with undulations designed to optimize water flow. This design facilitates efficient water flow in the vertical direction and increases heat exchange in counter-flow cooling towers. Vertical flow packing is suitable for counterflow cooling towers where water flows against the direction of air movement.

Anti-sediment packing

This type of cooling tower packing is designed and built to minimize scaling and sedimentation problems. These packings improve the long-term efficiency of the cooling tower and minimize maintenance needs by reducing the possibility of sediment formation on the packing surfaces.

Sediment packing is also an ideal option for cooling towers in environments where water quality may lead to sedimentation problems.

Advantages of cooling tower splash packing

Splash packing is a simple design that has several advantages. Splash packing helps the heat exchange processes in the cooling tower and increases the efficiency of the cooling tower. In cooling tower applications, where the objective is to remove heat through the interaction between water and air, splash packing plays an important role. Below are some of the key benefits associated with using splash packing.

Cost-effectiveness

One of the primary advantages of splash packaging is its affordability. It has a relatively simple design and consists of spray bars or grids placed at the top of the cooling tower. The simplicity of the design makes splash packing an economical and cost-effective choice, especially when budget constraints exist. In addition to having a lower initial installation price, splash packing also has a reasonable maintenance price. The efficiency and cost-effectiveness of splash packing make it an attractive option for various applications.

Ease of maintenance

Splash packing is known for its ease of maintenance. Its design is such that it is easy to inspect and clean. Maintenance personnel can easily access spray bars or grids and ensure that any possible debris or contaminants are removed quickly. This ease of maintenance contributes to overall cooling tower reliability and minimizes downtime and associated costs.

Versatility

Splash packing is particularly suitable for cross-flow cooling tower configurations. In cross-flow cooling towers, water flows vertically over the splash packing, while air moves horizontally. The design of the splash packing is fully coordinated with the cross-flow arrangement and maximizes its efficiency in facilitating heat transfer. This versatility makes splash packing a good choice in applications where cross-flow cooling towers are used.

Effective distribution of water

The splash packing design improves the effective distribution of water inside the cooling tower. When water is sprayed onto sprinkler bars or grids, it breaks up into tiny droplets, creating a pattern of dispersed water. This dispersion causes the entire packing surface to receive water and increases the contact between water and air. Effective water distribution contributes to optimal heat exchange efficiency, which is a critical factor in the performance of cooling towers.

Suitable for medium heat transfer conditions

Splash packing is suitable for applications that require moderate heat exchange. Although in this case, splash packing may be less efficient than advanced packing. However, it is still a cost-effective option. For this reason, splash packing is suitable for a wide range of industrial and commercial applications with different cooling needs.

Resistance to precipitation

Splash packing design with an open and simple structure is more resistant to sediment compared to other types of packing. Fouling, which includes deposits accumulating on packing surfaces, can negatively affect heat exchange efficiency. Splash packing’s resistance to sediment contributes to its reliability and longevity and requires less cleaning or maintenance.

Compatibility with water quality

Splash packing is more compatible with water quality compared to other types of packing. In addition, splash packing is more resistant to chemical changes in water. This adaptation can be very efficient and useful in situations where water quality control is difficult or there are limitations in water purification.

Finally, it can be said that using splash packing in cooling towers has many advantages. including cost-effectiveness, ease of maintenance, versatility in cross-flow settings, effective water distribution, suitability for moderate heat transfer needs, resistance to sedimentation and compatibility with water quality, however, splash packing can be an option for all cooling towers. Not ideal.

Cooling tower packing material

The choice of packing materials plays a fundamental role in determining the efficiency and durability of cooling towers. In this exploration, we examine the various materials commonly used in cooling tower packing and explain their properties, benefits, and applications.

1. Polyvinyl chloride (PVC)

– PVC is a popular and affordable material used in cooling tower packing. Known for its corrosion resistance and durability, PVC is able to withstand harsh environmental conditions.In addition, they are light and easy to install.

Advantages of PVC packing

Excellent resistance to chemical corrosion

High longevity and durability

Cost-effectiveness

2. Polypropylene PP

Polypropylene is another corrosion-resistant thermoplastic that is usually used in cooling tower packing. It offers good chemical resistance and is suitable for applications where aggressive water conditions exist. Polypropylene shows high strength and resistance to mechanical stresses.

Advantages of PP polypropylene packing

Very high chemical resistance.

Proper strength and resistance to mechanical stress helps the durability of packing.

Resistance to chemical and mechanical wear

3. Polyester reinforced fiberglass FRP

FRP fiberglass packing is another type of packing that has high strength and elasticity. FRP fiberglass has good resistance to chemical and biological deposition. These packings are generally used in waste disposal industries.

4. Stainless steel

Stainless steel packing is known for its high strength, corrosion resistance and durability. It can withstand extreme temperatures and harsh environmental conditions. Stainless steel has a very good resistance to corrosion caused by water with a high mineral content.

5. Copper alloys

Copper alloys such as brass and bronze offer a combination of strength, corrosion resistance, and antimicrobial properties. These alloys show good thermal conductivity. The antimicrobial properties of copper alloys prevent the growth of microorganisms and help keep the cooling tower clean. Good thermal conductivity increases the heat transfer efficiency in the cooling process. Copper alloys are often chosen for applications where microbial growth is a concern.

Choosing the right material for cooling tower packing includes considering factors such as specific environment, water quality, temperature changes, and intended use. Each material has its own unique set of advantages and disadvantages. Finally, the correct selection of packing materials contributes to the overall efficiency, longevity and reliability of the cooling tower.

The price of cooling tower packing

The price of cooling tower packing depends on various factors. Several factors such as installation and maintenance cost, type of packing and many other factors affect the price of cooling tower packing. In the following, we will examine each of these factors.

1. Type of material

The choice of materials significantly affects the price of cooling tower packing. Different materials such as polyvinyl chloride (PVC), polypropylene (PP), fiberglass reinforced polyester (FRP), stainless steel and copper alloys are available at different prices. While materials such as PVC and PP are cost-effective, high-performance materials such as stainless steel and FRP may carry higher initial prices but offer long-term benefits in terms of durability and reduced maintenance.

2. Type of packing

There are different types of cooling tower packing, each of which has design and performance features. Splash packing, film packing, structured film packing and others are different in terms of complexity and effectiveness. Advanced and high-efficiency packaging designs are expected to have higher production prices.

3. Installation costs

The installation process is significantly effective in the price of cooling tower packing. Prices for labor, including skilled technicians or installation contractors, vary based on factors such as system complexity, tower height, and packing type. Some packing materials, such as lightweight plastics, may simplify the installation process and potentially reduce labor costs. However, more complex packing designs or materials that require specialized handling may increase installation prices.

4. System size and configuration

The size and configuration of the cooling tower system directly affects the amount of packing material required. Larger cooling towers require more packing and increase the cost of materials. In addition, the cooling tower configuration—whether crossflow or counterflow—affects the type and amount of packing required.

5. Maintenance

While initial pricing is a key consideration, evaluating long-term maintenance and life-cycle pricing is just as important. Some materials, such as stainless steel or FRP, may have higher upfront costs, but they are more durable and require less maintenance, making them cost-effective in the long run.

6. Compliance with environmental regulations

Compliance with environmental regulations and sustainability goals can affect the choice of cooling tower packing. Materials that meet environmental standards may have additional certifications or manufacturing processes that affect prices. However, the long-term benefits of environmentally friendly materials, such as reduced water consumption or energy efficiency, can be cost-effective in the long run.

7. Water quality and purification

The quality of water in the cooling tower system affects the selection of packing materials. Corrosion or fouling resistant materials may be more expensive. When evaluating the cost of cooling tower packing, the cost of water treatment solutions, such as antifouling or biocide treatments, should also be considered.

Selling cooling tower packing

Selling cooling tower packing requires a strategic and comprehensive approach that considers the broad aspects of customer needs and experiences. Providing advice to customers regarding the choice of packing type is one of the most important factors that should be considered in the sale of cooling tower packing.

Building trust in customers by showing expertise in installation and providing effective after-sales service is also vital in selling cooling tower packing. In addition, providing comprehensive information and awareness of industry trends and innovations is important to create a planned cooperation with customers as future partners.

العربية

العربية فارسی

فارسی