Cooling towers work based on surface evaporation. In the old cooling towers, they had a low capacity due to the lack of cooling packings, and for this reason, we had to build cooling towers with very large dimensions to achieve high capacities, especially in industries and power plants. Cooling packings increase the evaporation and cooling capacity of the cooling tower by making changes in the flow of water and air.

Splash grade packing is a special type of cooling tower cooling packing that is used for cases where the water entering the cooling tower has high hardness. These cooling packings, which are also known as mesh packings, are made of polypropylene (PP) and are used in water with a very high level of hardness and suspended particles (TSS) in the water entering the cooling tower. In grid splash packings, the distance between the grids is such that no deposits are formed on the packing, so the performance of the cooling tower does not decrease under the influence of these deposits.

Types of splash grade packing

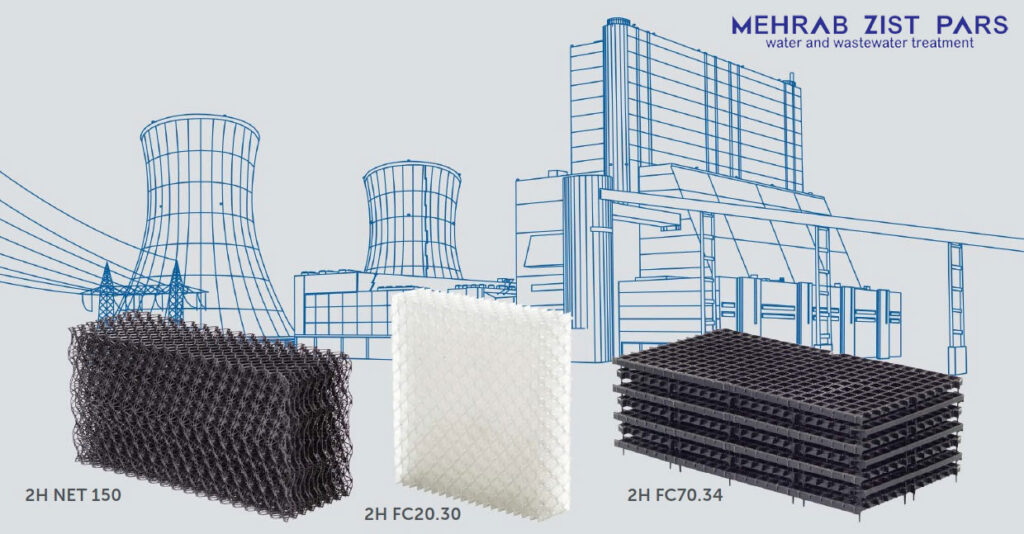

Splash grade packings have different types according to the type of construction material, design and dimensions. In this section, we examine two types of models of packing grid splash.

Packing grade splash GR60X60

Packing grade splash GR60X60 is made of polypropylene. Its blocks are square and measure 60 x 60 cm with a height of 50 cm. This splash grade packing model can work up to 90 degrees Celsius without any problem or deformation. The distance between the sheets is 5 cm and the water inlet size is 34 mm.

FC 70.34 FC 70.34 splash grade packing

Packing grade Splash FC 70.34 is made of polypropylene. Its blocks are square and measure 100 x 100 cm with a height of 50 cm. This splash grade packing model can work up to 90 degrees Celsius without any problem or deformation. The distance between the sheets is 5 cm and the size of the water inlet is 34 mm.

Use of splash grade packing

The design of the packing grid splash of the cooling tower minimizes the risk of sedimentation and settling of particles in the water entering the tower. The configuration of the splash grid packing reduces the possibility of particles settling on the packing surface, which is a common problem in cooling towers. This feature is especially useful in areas where water hardness or suspended solids create challenges for the use of other cooling packings.

Splash grade packing is mostly used in power plant concrete and fiberglass cooling towers. But its use is not limited to these cases and it is also widely used in the following industries:

Production and construction of air conditioning equipment and facilities such as air conditioners, air washers and evaporative condensers

Water treatment and sewage (sewage) that serve as sewage media for bacterial growth

Industries related to steel, refineries, petrochemicals, in general, industries where the quality of circulating water is in the category of polluted water.

In all cooling towers, the circulating water has high hardness and a lot of salts.

In all industries where circulating water has high fat and its quality is low.

In air conditioning facilities that use water chillers and the quality of the chiller’s compensation water is low, for example in cities such as Ahvaz, Kerman, Qom, etc.

Advantages of grid splash packing compared to other cooling tower packings

Splash grade packings are more resistant to ultraviolet rays than other types of cooling tower packings and are less prone to powdering and brittleness over time. Also, the lifespan of these packings is higher and they have higher thermal resistance. Splash grade packings can work up to 120 degrees Celsius without any deformation.

Due to the material of splash grade packings, which are often made of various polymers, they have a high resistance to corrosion and wear. These packings can be washed with acid and are very clean. Finally, due to their extraordinary structure, sedimentation will be very low and the need for washing and cleaning is less in these packings than in other cooling tower packings.

Another advantage of Splash Grid packing is its modularity, which makes it much easier to replace and maintain the packing. Due to the modularity of splash grade packing, any part of the packing that has a problem can be replaced without damaging or replacing other parts.

The constituent structure of splash packings

Cooling tower splash grade packing is characterized by its grid-like structure. This packing consists of interconnected channels or networks that increase the amount of uniform distribution of water and provide maximum contact of water with the air flowing in the tower.

The working of splash grid packing is in such a way that the network-like structure of the water is made into small droplets and the contact surface of the water with the air inside the tower increases. This spraying mode increases the number of times the water particles collide with the packing networks, and increasing the number of collisions means that the water particles do not have a chance to settle and deposit.

In the past, splash grade packing was made of wood, but today it is made of materials such as ABS, polyethylene, polypropylene and polystyrene, which guarantee the durability and resistance of the packing against harsh environmental conditions in cooling towers.

Features of splash grade packing

1. Non-precipitability

Due to the integrated structure and no surface in the spray pockets, these packings prevent the sedimentation of the cooling tower.

2. Resistance to acid washing and chemicals

These packings have significant resistance against the effects of acid washing and other chemicals.

3. High useful life and good durability

Due to the high-quality and resistant structure, splash packings have a longer service life than other cooling packings.

4. Increasing the efficiency of the cooling system

These packings improve the efficiency of heat transfer and increase the efficiency of the cooling system.

5. High strength and good flexibility

The robust structure increases the strength of the packing, while maintaining its flexibility.

6. Temperature tolerance

These packings can withstand temperatures up to 90 degrees Celsius permanently and up to 120 degrees Celsius during temporary work.

7. Ease of installation and maintenance

The ability to replace and fast installation along with ease of maintenance are the features of these packings.

8. Maintaining efficiency against hard and polluted water

These packings maintain their effectiveness against high hardness water as well as polluted water of industrial cities.

9. Low pressure drop

The pressure drop in this type of packing is much less, this optimizes the performance of the system.

10. Special surface suitable for heat exchange

The special structure and surface of the packings (130 square meters per cubic meter) provides the optimal heat exchange to increase the performance of the tower.

How to install grid splash packing

The installation of packing grid splash is designed in such a way that it does not require any special support. This packing is hung inside the cooling tower using steel wires. This part is known as a modular unit with a structure that is easy to replace, maintain and install. To install this packing, as mentioned, steel wire and cable and components called spider are used in the cooling tower system.

Splash grade packing price

The price of splash grade packing depends on various factors such as the type of construction material, the purity of the material and the thickness of the grids, its model, the requested size and the type of design. But in general, the price of packing grade splash is economical and affordable due to the increase in the capacity of the tower, which is achieved as a result of its installation.

For more information about the price and purchase of packing grade splash, as well as receiving expert advice, contact our experts at Mehrab Zist Pars.

Selling all kinds of splash grids

Grid splash packings are designed and manufactured for different applications according to the construction material and type of grid. Mehrab Zist Pars Company is one of the largest distributors of all types of splash grade, which provides its customers with the best splash grade packings for various industries. In addition to selling all kinds of splash grids, you can contact our experts for support, repair and price advice for splash grid packing.

العربية

العربية فارسی

فارسی