Applications of lamella plates (clarifier)

Lamella plates are a very important equipment in the water purification and clarification process. In this article, we are going to examine the use, performance and types of lamella plates. If you intend to buy or familiarize yourself with Lamela pages, we suggest you stay with us until the end of this article.

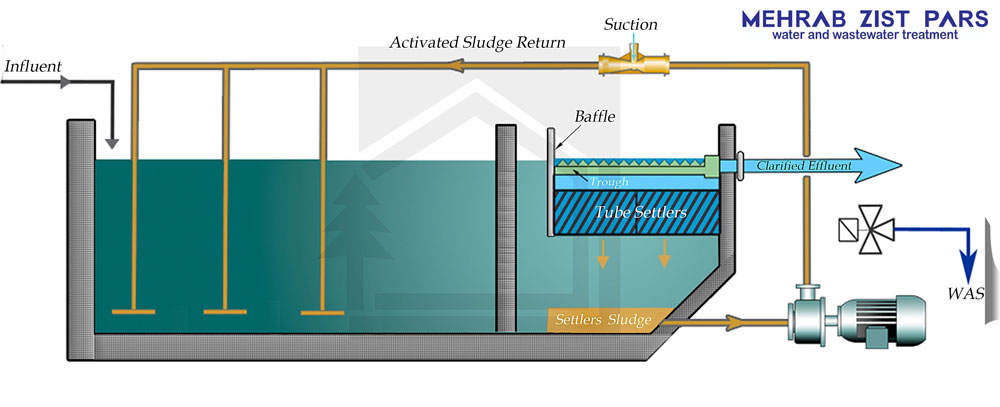

Lamella plates (clarifier) are widely used in water purification systems, especially in clarifiers and settling tanks. The main function of lamella plates is to increase the settling of suspended particles and solids in water, which makes it easier to separate clean water from impurities. These plates are used in various industries such as municipal water treatment plants, industrial wastewater treatment facilities and even in smaller sizes for residential or commercial purposes.

The performance of lamella plates

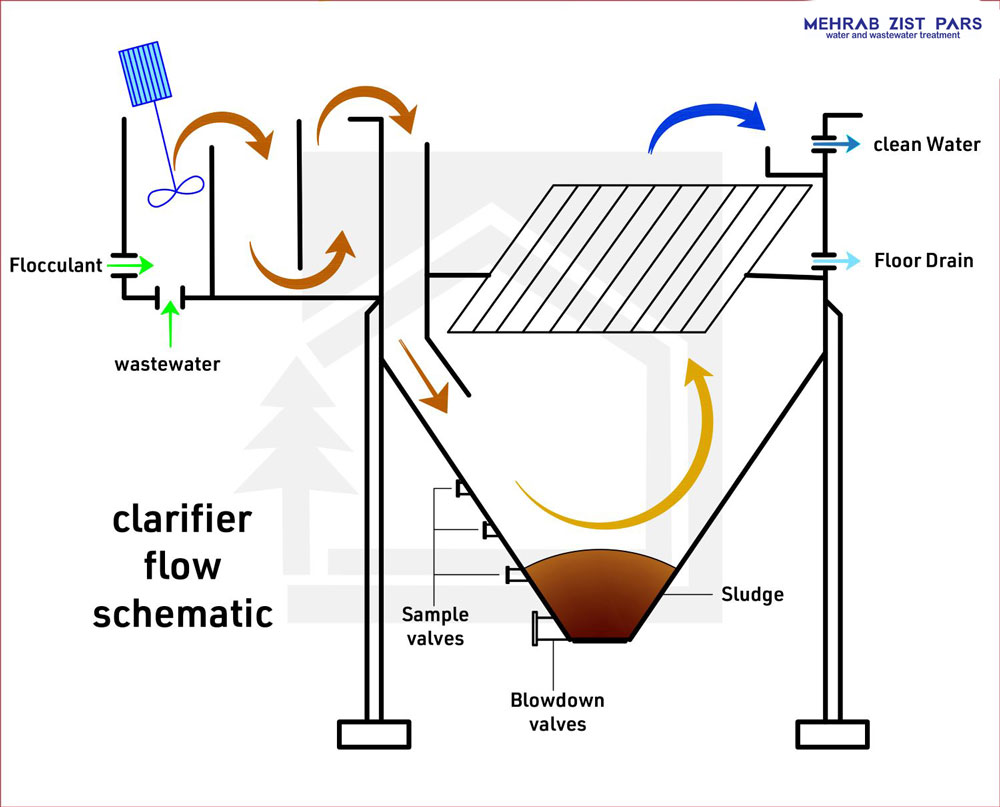

Maybe you have a question about how the lamella plates work? The performance of lamella plates relies on gravity. Imagine a bunch of slanted pages in a box. When the dirty water passes over these plates, due to the gravity of the soil and solid particles suspended in the water, they fall down with the help of gravity. The tilting design of the plates makes this happen faster and in a smaller space. In fact, these plates are like a slide for dirt. As the water moves along the plates, the soil slides down and stays there, while the clarified water moves up.

Lamella plates often have a viewing hatch. With the help of this inspection window, you can check the condition of these plates in terms of the amount of sedimentation and make sure of their correct operation.

Types of lamella plates (clarifier)

Different types of lamella plates are designed and produced in Mehrab Zist Pars company. Each of these pages is designed and built based on a specific need and application. In the following, we briefly examine some of the most common types of lamella plates.

Parallel lamella plates

Parallel lamella plates can be considered the most common type of lamella plates. which is made of a number of closely spaced parallel plates mounted at a certain angle. The sloped design provides a larger surface area for particles to settle, resulting in more fouling.

Honeycomb plates

Honeycomb plates consist of a number of lamella plates arranged in a honeycomb pattern. In this type of lamella plates, a large surface is included in a limited volume. Honeycomb plates are used in most large refineries.

Lamella plates with cross flow

Cross-flow lamella plates (clarifiers) have inclined plates arranged in a cross-flow configuration. This design helps to direct the flow horizontally and optimize the separation of solids from the liquid. Cross-flow clarifiers are suitable for applications where a continuous flow of treated water is essential.

Design and manufacture of lamella plates

The design of lamella plates requires careful consideration of factors such as the required settling area, water flow rate, and the characteristics of the particles being removed. Lamella plates are usually arranged at a certain angle, creating a series of inclined surfaces. The materials used are also different. The choice of material depends on factors such as chemical resistance and durability.

The manufacturing process includes precise cutting and molding to ensure uniformity in sheet dimensions. Depending on the customer’s needs, these sheets can have unique properties in terms of hydrophilicity or hydrophobicity with the help of surface treatments and machining operations. Quality control measures are essential throughout the manufacturing process to ensure that standards for performance and durability are met.

The price of lamella plates

The cost and price of lamella plates can be different based on factors such as materials used, dimensions and manufacturing processes. Plates made of specialized materials or with complex designs may cost more. In addition, factors such as the volume of sheets required for a particular project can affect the price of lamella sheets. To know the price and purchase of lamella sheets, you can contact the sales experts of Mehrab Zist Pars Company.

What issues should we pay attention to when buying lamella plates?

If you intend to buy lamella sheets, you should pay attention to important things. Buying lamella sheets requires knowing some points before anything else. In the following, we point out the most important points that should be paid attention to when buying lamella sheets.

Purpose and need

Before doing anything, you must identify your needs and goals correctly and clearly. Lamella plates may be designed for various purposes such as settling, clarification or sludge separation. Understanding your needs is very important in choosing the right type of lamella plates.

Material type of lamella plates

Lamella plates are produced using different materials such as polypropylene, PVC, polycarbonate and metals. The choice of material should be based on factors such as chemical resistance, durability and the nature of the treated material. Before purchasing, make sure that the selected material meets the requirements of your water treatment process.

Design of lamella plates

Before buying, be sure to pay attention to the design of the lamella plates.The arrangement, angle and distance of the plates can affect their efficiency in sedimentation and separation of particles. The design should be suitable for the flow rate and characteristics of the treated water you need.

Screen size and surface area

Determine the required size and surface of the lamella plates based on the volume of purified water required. The size of the plates affects the volume of the clarifier or settling tank. Ensuring sufficient surface area is essential to achieve proper settling of particles.

Lining or covering the lamella plates

Some lamella plates may have coatings or linings to improve their performance. Creating these covers may or may not be necessary depending on your needs. Considering that the knowledge of this issue is completely specialized, it is better to get expert advice in this field from the experts and consultants of Mehrab Zist Pars company before buying lamella sheets.

Manufacturer Reputation:

Buy lamella plates from reputable manufacturers or suppliers. Research the manufacturer’s reputation, their experience in the industry, and whether their products meet industry standards. Reviewing the opinions of former customers can also help you in this field.

Sale of lamella sheets in Mehrab Zist, Pars

As a reliable supplier and manufacturer, Mehrab Zist Pars Company plays a decisive role in the distribution and supply of lamella sheets. This company provides a platform for customers to access high quality lamella plates suitable for various applications. Mehrab Zist Pars Company is committed to meet the needs of customers by producing high-quality plates in accordance with relevant standards.

العربية

العربية فارسی

فارسی