Cooling towers are necessary for many industries. The installation of cooling towers has various advantages, including reduced energy consumption, reduced cost, longer lifespan, and less maintenance. Due to such advantages, many industrial units consider the installation of cooling towers as optimal and desirable for their units. Various factors such as proper maintenance, use of high-quality parts in case of need for replacement, etc. affect the performance of cooling towers. One of the critical elements of cooling towers is the cooling tower drip catcher. These drippers are also known as drift eliminators. They play a vital role in the proper functioning of cooling towers. In the following, you will get to know the concept of cooling tower drip catcher, its advantages, types and efficiency.

What is a cooling tower drip catcher?

The cooling tower drip catcher prevents water droplets from splashing out or towards the suction fan. In fact, this piece does not allow water droplets to escape from the cooling tower. This type of performance has made the drip catcher one of the main components of the cooling tower. In any cooling tower, water is lost due to the evaporative cooling process. This evaporation is usually in the form of pure water vapor and does not cause any harm to the environment. However, drift is the undesirable loss of liquid water from the cooling tower. They are the small droplets that are trapped in the exhaust air stream. These water droplets have the same concentration of chemicals and mineral impurities commonly found in cooling towers.

Cooling tower drippers are designed to capture large water droplets that are trapped in the cooling tower airflow. These drippers prevent water and dust droplets from leaving the cooling tower. Drip deflectors (thrust eliminators) do this by redirecting the droplets and slowing them down as they hit the walls. As a result, water drops fall back into the tower.

The cooling tower drip catcher ensures that the water recycling process is in excellent condition. The positive performance of this drip catcher is not limited to saving water, but it also prevents the release of water contaminated with chemicals in the environment. To define the cooling tower drip catcher, it can be said that its main purpose is to prevent environmental pollution. This drip catcher also keeps the drift rate to a minimum and reduces the frequency of pressure drops in the cooling tower.

Efficiency and benefits of cooling tower drip catcher

Installing a cooling tower drip catcher in cooling towers has several advantages, especially in large-scale production units. These benefits are not only for the owners, but also help to improve the environment. Let’s take a look at some of the top benefits of these drippers.

It prevents the fields and nearby roads from freezing.

It keeps electrical components and plumbing systems in good condition by preventing corrosion.

With the help of the cooling tower drip catcher, it is possible to avoid the short circuit that often occurs due to the damage of the electrical components.

By using a cooling tower drip catcher, they ensure that the release of hazardous chemicals into the environment is significantly reduced.

By using drippers, it becomes possible to save water on a large scale.

Water pressure drop in cooling tower happens frequently. This pressure drop is reduced with the help of the cooling tower dripper.

With drippers in cooling towers, there is no need for additional water treatment.

The lifespan of the cooling tower is also increased.

Reduces energy consumption significantly.

How the cooling tower drip catcher works

When the water droplets hit the cooling tower dripper, the blades and plates of these drippers cause the loss of the kinetic energy of the water droplets and return them downwards. These parts prevent water droplets moving towards the fan and trap them.

Different types of cooling tower drippers

There are different types of drift removers in the market. However, most of them can be divided into two categories, one is cross-flow eliminators and the other is cross-flow eliminators.

Counter-flow cooling tower dripper: The counter-flow cooling tower dripper mechanism allows vertical air flow at the top of the tower through the fillers. In this case, water flows from top to bottom. This mechanism expels more air at a faster rate than the air intake process. Counterflow eliminators have various advantages such as low energy consumption, low maintenance and low pump head.

Cross-flow cooling tower drippers: Counterflow cooling tower drippers have vertical airflow, while cross-flow eliminators have horizontal airflow. In both types, the water flows downwards. Cross-flow drippers are also known for their use of fillers. This dripper is affordable. Using this type of cooling tower drip catcher has several other advantages, including low noise, minimal maintenance, excellent performance, and low energy consumption.

Cooling tower drippers also come in different designs, but this model can have a counter or cross flow mechanism. This issue depends on the installation model of the part, which is installed vertically or horizontally. Another type of classification of drippers can be done based on the shape and form of the design. These types of features also create different types of cooling tower drippers.

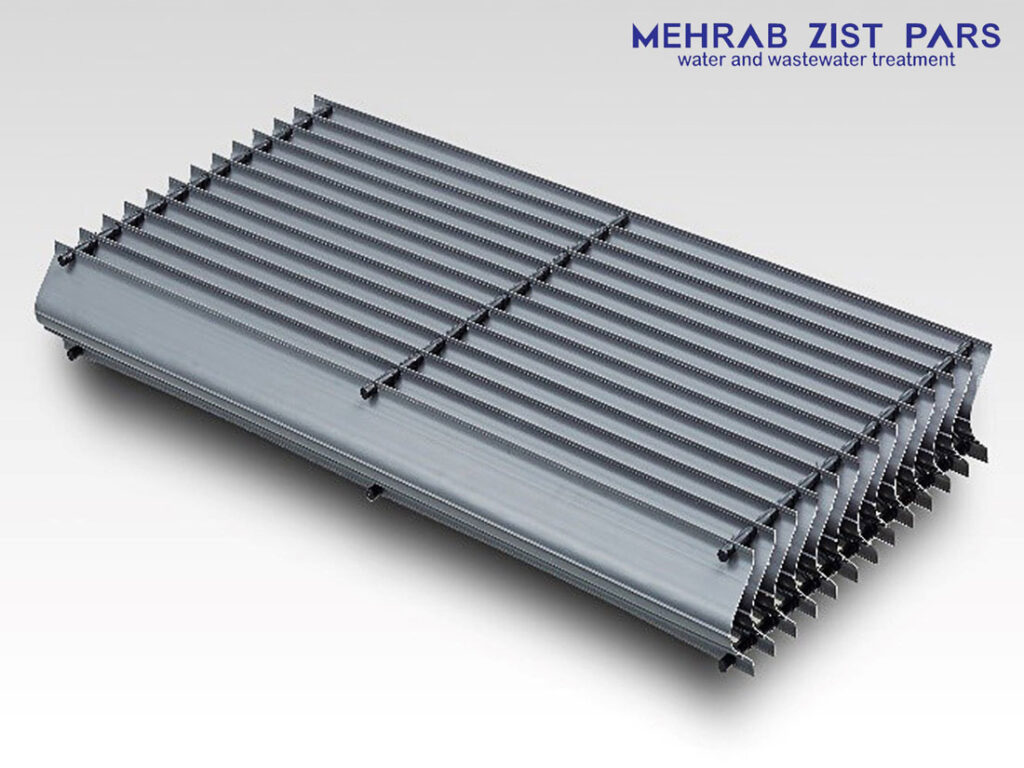

Blade: Blade style drippers generally have metered blades that are capped at both ends. These blades are light but very durable.

Cellular: These drippers have a cellular or honeycomb design and look very structured and organized. The function of this drip catcher is that it deflects water drops in three different directions. This cellular structure creates a centrifugal force and ensures that no water droplets are thrown out of the cooling tower.

Cassette: This cooling tower drip catcher model is easy to install and remove due to its strength and light weight. In addition, this model has a better lifespan than other designs and can be used in retrofitting.

Filled with carbon black: This type of drip catcher is filled with carbon black to resist UV rays, but is mixed with the original material to increase longevity. Such fillers also make this dropper model resistant to corrosion.

The material of the cooling tower drip catcher

Cooling tower drip catcher can be designed and produced with different materials.

Polypropylene: This is a recyclable material that is a combination of fiber and plastic. Polypropylene has better thermal resistance than PVC, while it has a very good resistance to moisture. However, when this material is continuously exposed to UV rays, it degrades.

Polyvinyl Chloride (PVC): This material is very popular and known as the most economical material. These materials are resistant to corrosion, but toxic substances are also found in their compositions.

Metal: Steel thrust eliminators are popular for use in containerized cargo and higher temperatures. Metals are not resistant to corrosion, but the right coating can increase their resistance.

The price of the cooling tower drip catcher

Various factors affect the price of the cooling tower drip catcher. The weight of the drift eliminator, the type of drip eliminator, the production material of the drift eliminator, the price of raw materials such as polypropylene and granules, the thickness of the drip eliminator, the cross section, the capacity and dimensions of the cooling tower are some of the things that change the price of the cooling tower drip eliminator. For example, the price of a blade model dripper is higher than a cellular dripper (bees nest).

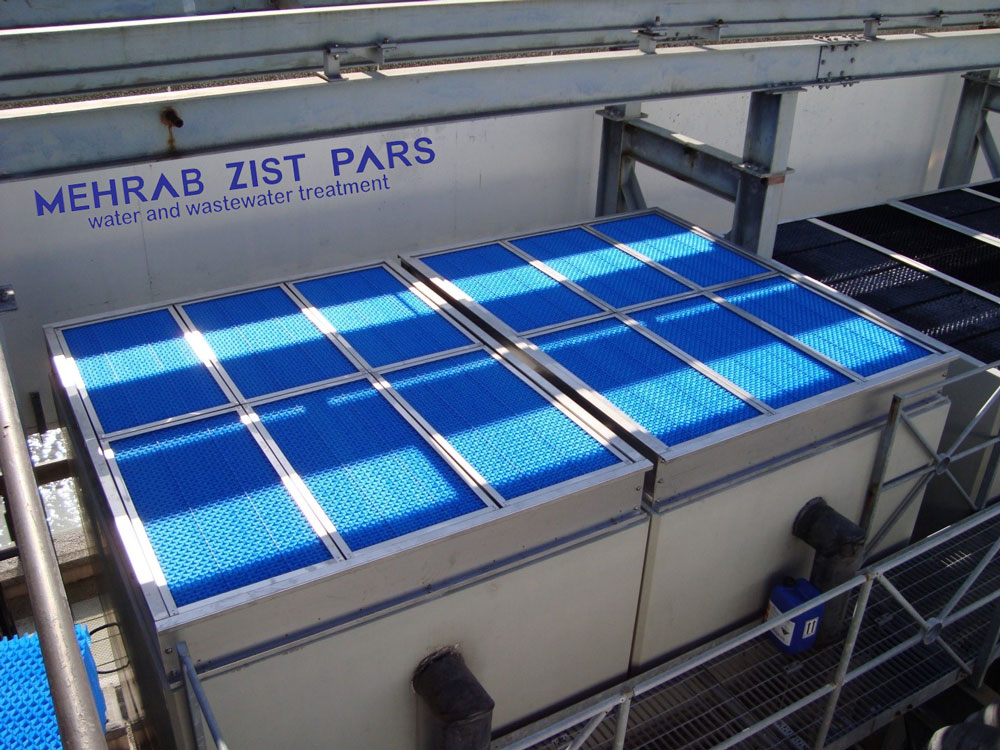

Installation of cooling tower drip catcher

The cooling tower can have different models of cone, bar, cube, crossflow, etc. Nevertheless, in most of them, the installation of the drip catcher is done in the same way. In most cases, the cooling tower drip catcher is installed before the cooling fan and above the cooling tower nozzle. In the conical cooling towers, the dropper is also installed on the top of the nozzle outlet pipes and fixed with fasteners. When the steam or water droplets hit the drip catcher, they flow to the bottom of the cooling tower.

Cooling tower drip catcher for sale

The sale of drippers in different brands and models is carried out by Mehrab Zist Pars Company. These models are different in terms of design, construction material and even performance. On the other hand, the production brand of droppers may also affect their production quality. In order to enjoy the optimal and favorable sale of these industrial parts, it is better to choose a reliable and reliable store to buy, because in this case you will also enjoy the guarantee of the authenticity and health of the product.

Important technical features for purchasing a cooling tower drip catcher

Different models of drift eliminators with different specifications are available in the market. Here are some of the most common specifications of drift eliminators. To buy a cooling tower drip catcher, focus on its technical features:

Installation type of drip catcher which can be counter flow or cross flow.

Design type (cell type, blade type, cassette type, etc.)

Dimensions

The distance between the blades and their thickness

Capacity

sheet size

What are the ideal characteristics of a dripper?

Now you know how to choose a drift eliminator model that suits your needs. To buy a cooling tower drip catcher, you should check the following features:

The cooling tower drip catcher must be approved and manufactured with safety regulations in mind

It should be easy to use and maintain

High performance

Affordable

It should be adjustable and flexible according to the need

Drip components

The cooling tower dripper is one of the essential parts for the cooling tower. These parts have a simple structure and this makes them very easy to use. Installing a drift eliminator in the cooling tower is also very simple.

Seals: Seals are added when installing the cooling tower drip catcher. Its main function is to prevent bypass drift. This structure ensures that no drop of water is lost during the rerouting process.

Filter: As we discussed, a drift eliminator prevents water contamination. This filter ensures that no harmful chemicals are released into the environment.

Walls or Blades: There are many different types of wall and blade designs for drippers, but they all serve the same purpose and that is to return water back into the cooling tower for reuse.

summary

It doesn’t matter what type of cooling tower you use, either way, installing a drift eliminator can be critical to your project. In this article, we have discussed the benefits of cooling tower drip catcher and found that it not only reduces cost but also helps to improve the environment. In fact, drift remover can work as a useful product.

العربية

العربية فارسی

فارسی